Posted to News on 5th May 2021, 08:59

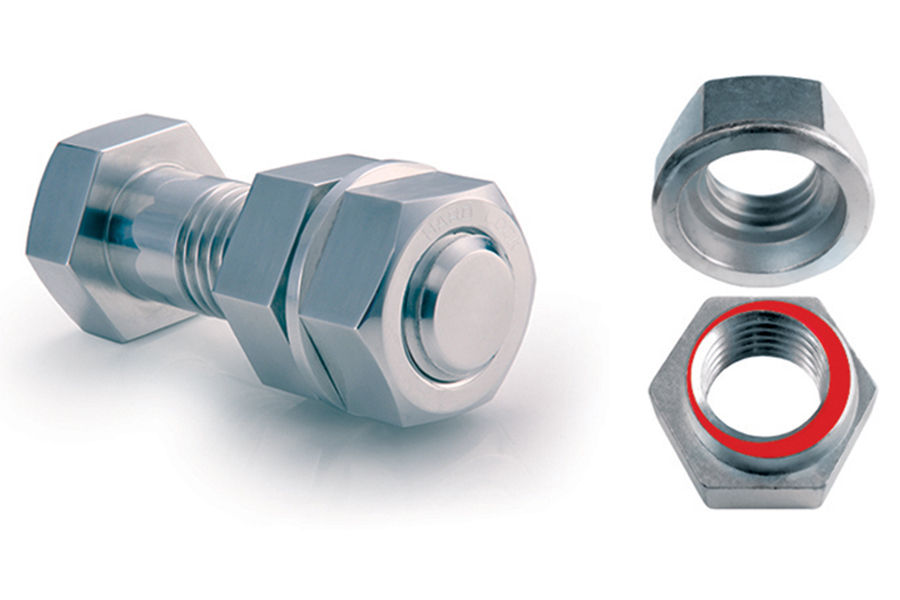

A fastener that resists loosening

Hardlock Nuts are used where a fastener must resist loosening, especially in high vibration environments. For example, they are used extensively on railway, automotive, wind turbine, mast, building, bridges, and machinery applications

How does it work?

The Hardlock Nut utilises the wedge principle. Instead of hammering a wedge between an application and screw thread to secure it from loosening, the Hardlock nut creates the ‘wedge’ mechanically. Firstly, the lower convex nut generates axial torque in the same way as a normal nut. Importantly this nut has a small eccentricity at the upper convex (highlighted in the accompanying illustration in red). Then, as the (symmetrical) upper concave lock nut is tightened against the eccentricity it generates a wedge effect perpendicular to the axis. This pushes the lower convex nut against the screw thread. When the upper concave nut is completely tightened, the Hardlock Nut produces a stable self-locking force.

Apart from its resistance to loosening, does the Hardlock Nut have any other advantages?

What machine builders and designers of all sorts of mechanical equipment may find useful is that if an application requires the locking nut to be serviceable, the Hardlock Nut’s performance does not deteriorate after multiple uses. So it can be removed and reinstalled without any detriment to performance. The design of the majority of alternative locking nuts is that they rely on prevailing torque, the theory being that if they are hard to put on then they should be hard to take off (or loosen). This can cause problems because they can damage the thread that they are applied to, or the fastener itself loses its ability to resist loosening after a few uses. The Hardlock Nut does not suffer from these problems.

Is the Hardlock Nut the only fastening product Staytite has available?

No. Staytite has a broad range of products and services to offer including fasteners, c-class components, consumables, vending, engineering solutions and stock management. Samples of all products are readily available, including Hardlock nuts. Our team of engineers is always on hand to discuss applications and offer experienced advice. For more information simply call Staytite on 01494 462322 or visit www.staytite.com

Staytite House, Coronation Road

Cressex Business Park

HP12 3RP

UNITED KINGDOM

0300 373 9029