Posted to News on 10th Feb 2021, 10:28

Precision automated coatings expertise for the aerospace industry

Oxford-based specialist Intertronics has contributed to a high-precision, bespoke Automated Masking system for a customer in the aerospace sector

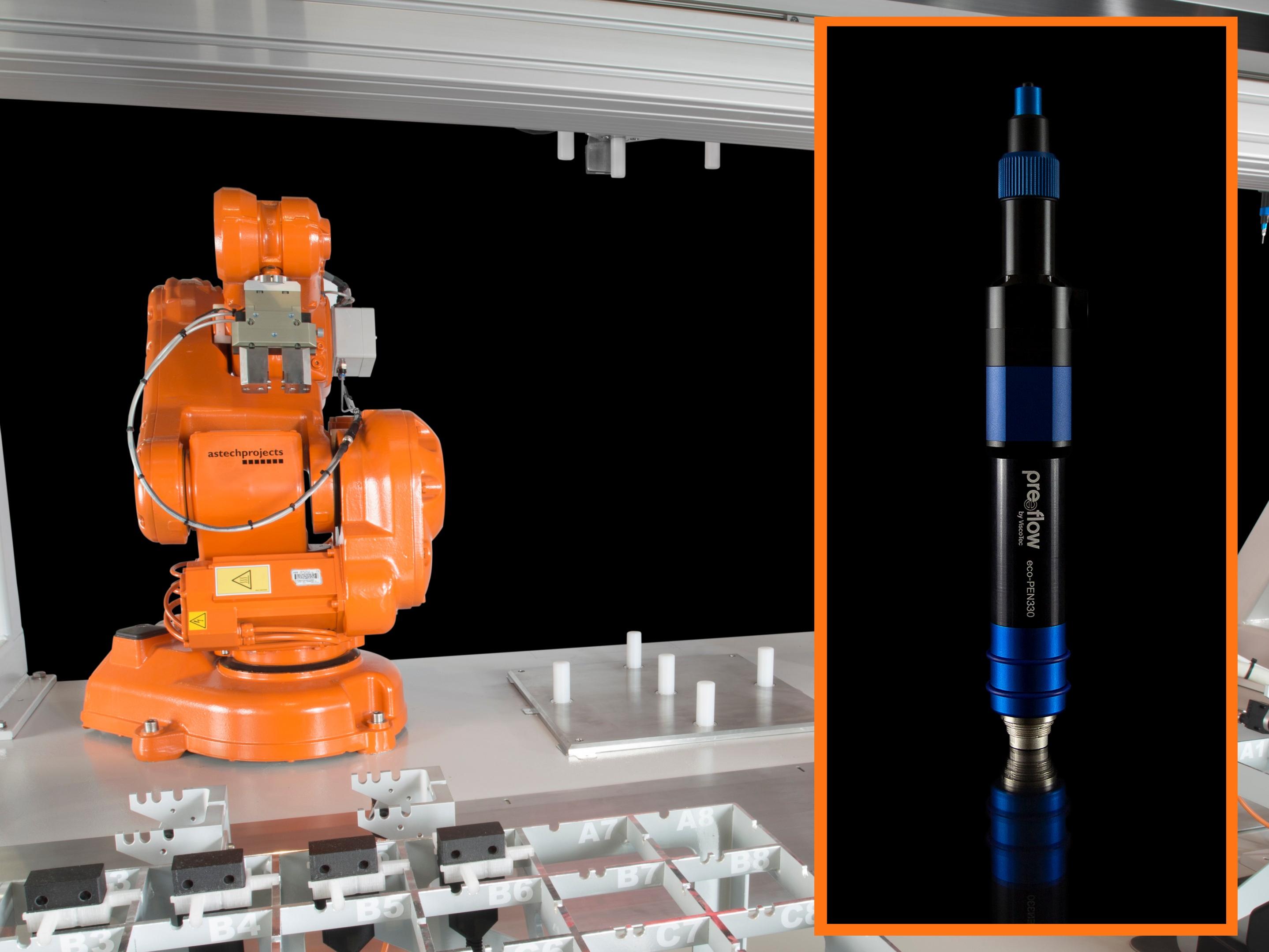

To assist with the development of a bespoke Automated Masking System for a leading UK aerospace company, automation solutions provider Astech Projects turned to adhesives and coatings specialist Intertronics. As part of the project, Intertronics supplied Dymax 717-R SpeedMask resin alongside a preeflow® eco-PEN450 dispensing system.

Astech Projects, part of the Schauenburg International group of companies, is a supplier of robotics and automation solutions to many advanced manufacturing and regulated industries including pharmaceutical, medical device, consumer healthcare, chemical, aerospace and automotive. The company builds systems from concept to completion on a custom basis, turning its hand to any application not currently available in the market.

Built to order

“We were tasked with building a bespoke Automated Masking System to mask complex areas of aircraft components and avoid precious metal coverage during the manufacturing process,” explains Craig Hamilton of Astech Projects. “The system was required to have the capability to mask 14 component variants whilst offering the functionality to add additional variants in the future. While masking and coating is a common application, automating it is not,” he continued. “Astech aimed to increase throughput, accuracy and masking quality by building a bespoke automated system which benefited from the expertise of adhesive and coating specialists Intertronics.”

A great match

Intertronics had already established that the Dymax 717-R SpeedMask product would effectively protect the precious metal during the manufacturing process and was therefore an appropriate choice.

“Once the masking resin had been selected, Intertronics worked with Astech to establish the success of the preeflow® eco-PEN450 as a dispensing mechanism,” explained Matthew Baseley of Intertronics. “The system was chosen because of its high accuracy — it gives a value greater than ±1% for 99% per cent of the time. The system also has no fluctuation in the volume of resin dispensed with any change in viscosity. By working with our customer we established that this was an appropriate dispensing technique for the application”.

Beasley also points out that in order to ensure that the curing process could be fully automated with a high throughput, Intertronics also supplied the appropriate curing equipment including high-intensity UV lamps to enable the resin to be cured quickly, in the range of 20 to 30 seconds.

Building a solution

Intertronics made its dispensing and curing equipment available to Astech for use at its Cheshire facility, thus enabling the company to complete two further proof of concepts projects prior to finalising the design for the automated system. To support Astech, Paul Whitehead and Matthew Baseley from Intertronics visited the facility and once the solution was tested and proven to be successful, Astech purchased the required coating, curing and dispensing equipment from Intertronics.

The fully automated system incorporates a 3-axis cartesian robot and two 6-axis robots working synchronously according to one robot programme. It also includes a high-definition vision system, masking dispensing system and UV curing station. On a batch-by-batch basis, the system can correctly identify and orientate 14 types of part against the preeflow® eco-PEN450, which accurately dispenses the Dymax 717-R SpeedMask product. The part is then taken to a curing chamber, where it is illuminated with high intensity UV. Once the process is complete, the component is returned to its original input location. The process repeats itself until the entire batch of components has been processed.

Intertronics continues to supply the customer with Dymax 717-R SpeedMask in 15-kilogram pails.

An automated process

“The main drivers behind the project were to accurately and repeatably mask the component,” said Baseley. “The final result dispenses to an accuracy of 100 microns, a great achievement. Astech Projects’ bespoke system offers its client a significant labour saving and increases throughput with the client now channelling 60 per cent of its components through the system.”

“There is great potential in the market for Astech to build automated systems for masking and coating applications,” explained Hamilton. “For example, medical devices, electronics and aerospace industries regularly use a masking process. We are now looking at other applications with the same client and its parent company, as well as with Intertronics.

“Intertronics is an extremely knowledgeable company, providing Astech with vital coatings expertise. They were great partners for this project and we look forward to working together with Intertronics again in the future,” concluded Hamilton.

If you’re a machine builder or systems integrator seeking adhesives expertise to complement your next project, get in touch with Intertronics on 01865 842842 or visit them here.