Posted to News on 8th Dec 2021, 08:57

Collaborative automation helps boost throughput and productivity

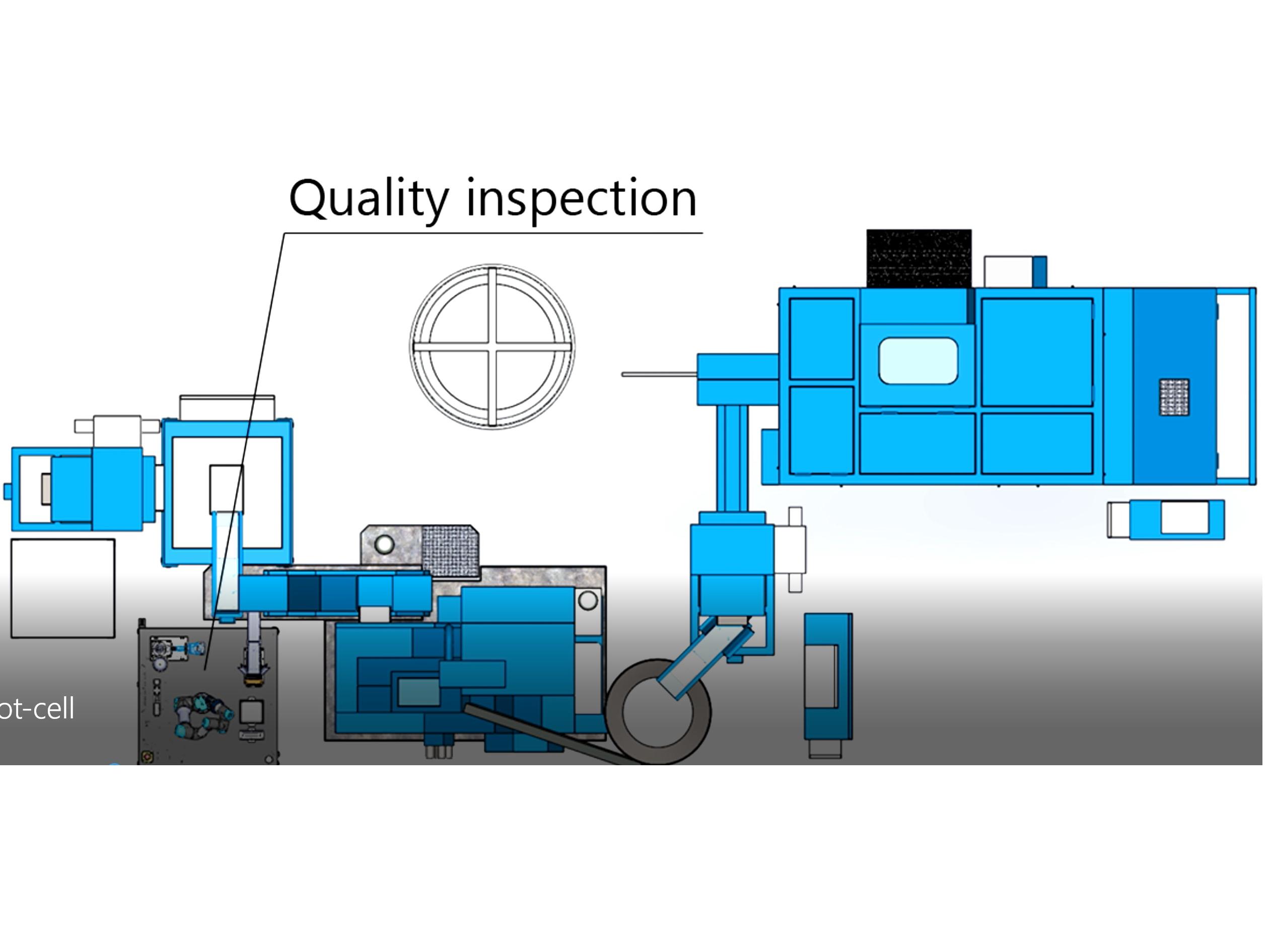

Stanley Engineered Fastening achieves automated quality inspection with Universal Robots

Global collaborative robot provider Universal Robots has confirmed that Stanley Engineered Fastening has successfully introduced robotic quality inspection using cobots at its Warrington facility.

15 UR3e cobots act as key components in its new cells for Breakstem autonomous manufacture, which have reduced product costs by approximately 10% and shortened lead times by up to 70%. They are producing around 350 million fasteners per annum from across the company’s product range.

“The new cells fully integrate four previously independent processes, boosting productivity and improving conditions for machine operators by eliminating 5.5 million pounds of manual handling per year,” it is stated. Within the manufacturing process, a UR3e cobot randomly selects a component for batch sampling and performs a pre-programmed quality inspection. This involves degreasing, drying, deburring and feature inspection through a digital micrometer. The cobot then performs an automated destructive test by placing the part in a Stanley Smart Gun to record the break load of the components.

Better profitability and shorter lead times

Vitalij Rodnov, advanced manufacturing engineer at Stanley Engineered Fastening, explains his reasons for automating quality inspection on the production line. “We needed to increase throughput and productivity, in order to meet demand across our fastener product range. Freeing up our machine operators from this repetitive task allows them to add more value elsewhere in the process, delivering better profitability and shorter lead times.”

Adds Mark Gray, country manager, UK & Ireland at Universal Robots: “Stanley Engineered Fastening is a great example of a company smartly using collaborative automation to make its business more successful and resilient. Our cobots are helping transform so many organisations whose potential would otherwise be constrained by labour shortages, limited production space or rising production costs.”