Posted to News on 3rd Dec 2020, 08:58

Dangers of vibrational fastener loosening

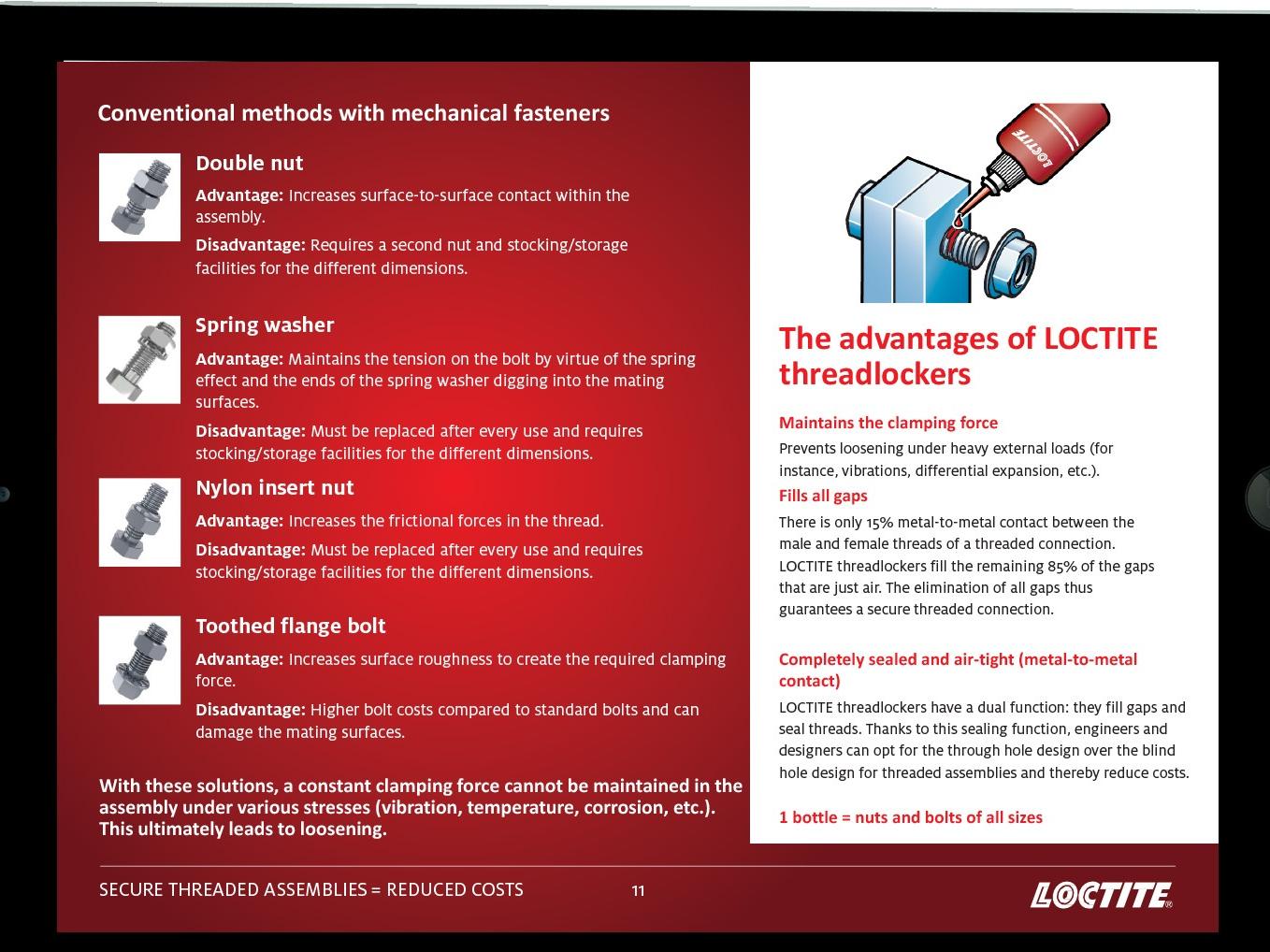

Newly released video highlights why threaded fastener assemblies can fail

Just released by Henkel Loctite the new video demonstrates the importance of locking threaded assemblies against vibrational self-loosening: the company has also made available an education guide on the subject. Several different methods of addressing the problem of self-loosening are common and some of them include the use of mechanical devices to lock threads and maintain the desired clamp load, says Loctite. Other solutions sometimes include a double nut that increases contact through more thread interface, a spring washer to increase bolt tension through its spring action or a nylon insert which creates interference between itself and the bolt threads.

Loctite states that the limitation of these methods is that none of them tackle the gap that exists between the threads of the bolt and nut. The gap appears tiny to the naked eye, but it is still large enough to allow side to side movement of the bolt within the nut caused by operational vibrations: a movement that may eventually cause the bolt to loosen, regardless of a mechanical device used to lock it. Henkel says its new video lasts less than a minute and shows the results that a failure can bring. It can be seen here.

An accompanying thread locking e-book released with the video expands on the subject of why threaded assemblies can fail. Henkel Loctite says that it provides a comprehensive introduction to the merits of adhesive thread locking, either as a stand-alone solution or to complement a mechanical thread locking device. It also guides the reader on the choice of adhesives available and how to disassemble a fixture once thread locked.