Posted to News on 3rd Aug 2022, 08:57

Electrically conductive adhesives and tapes

Electrically conductive adhesives and conductive adhesive tapes are now commonplace in manufacturing and have contributed immensely to the micro design of everyday consumer electronic devices.

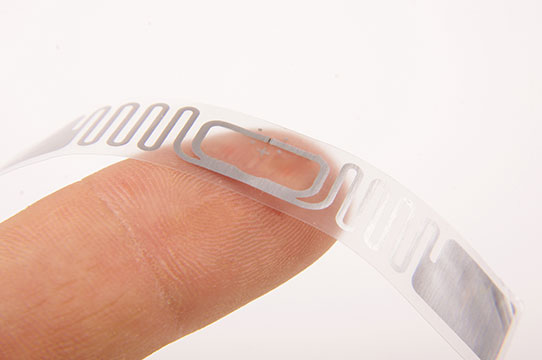

Examples include smart tablets, mobile phones, touch screens, TVs, medical devices, flexible PCBs, wearable conductive clothing, RFID tagging and RFI shielding. Conductive adhesives and conductive tapes have also seen an upswing in aerospace and automotive applications, too.

Electrically conductive adhesives are usually thermally curing epoxy resin-based adhesives, solvent based air drying adhesives/coatings or UV-curing acrylate-based adhesives augmented with metallic fillers, such as silver. Grade, shape, grain size and grain distribution of the filling material are critical influencers to optimising adhesive conductivity. In addition, a significant contributor to electrical conductivity is the adhesive curing process. Improper curing can cause a deterioration of performance and integrity of the bonded parts.

Electrically conductive adhesives are often used as a more effective alternative to conventional soldering. They are particularly suitable for making electrical contacts on temperature-sensitive substrates, as their curing temperature lies clearly below soldering temperature. In addition, the adhesives are much more flexible than solder and are therefore better able to withstand vibrations.

A further advantage over soldering is that conductive adhesives are lead free. There are two types of electrically conductive adhesives: isotropic and anisotropic. Isotropic conductive adhesives (ICA) are electrically conductive in all directions. They are used in applications such as chip contacting and bonding of electrically conductive SMDs.

Anisotropic conductive adhesives (ACA) contain special conductive particles in the µm range, which conduct electricity only in one direction. These adhesives are used, for example, in many sensitive structures on circuit boards, such as LCD connections or contacting flexible circuits to rigid PCBs, or for bonding antenna structures on RFIDs.

Eurobond Adhesives offers the Elecolit range of silver filled, single-component and two component conductive adhesives that can easily be applied with dispensers, jets, brushes or screen-printed. Both types can cure either at room temperature or can be accelerated by thermally curing. Innovative hardener systems in many of the one-part epoxy-based adhesives develop ‘cure’ within minutes and these can be used to connect heat sensitive components to printed circuit boards, wave guide plumbing, hybrid circuit assembly, connecting ground wires to components, making conductive tracks or pathways and bonding discrete devices and hybrid circuits.

Other applications include bonding conductive paths in heated car windscreens and mirrors, RFID applications, bonding batteries to foil/film, bonding flexible film LCDs to hard FR4 boards, circuit track repairs, populating PCBs etc, the list is almost endless.

Today of course, the range of conductive adhesives and electrically conductive adhesive tapes and their applications is vast and varied. Conductive adhesives and conductive tapes are tailored to suit almost any application. When selecting the right product for your specific project, it is important to consider the following points and discuss them in depth with your chosen specialist adhesive supplier:

- The type of dispensing method will you employ ie, syringe, stamp, screen print, jet manually applied tape?

- The type of conductive filler do you need ie Silver, Copper, Aluminium or Graphite.

- The viscosity of the adhesive perhaps a paste or a liquid adhesive?

- Whether it should be an Isotropic or Anisotropic adhesive?

- Which pot life best suits your particular application?

- Is there a specific cure time and cure method you need to employ?

- What volume resistivity does your application require?

- Does the application require a specific bond line thickness and or specific geometry? If so, then a bespoke die cut shape made from conductive adhesive tape may be best.

Shelf life and storage are important areas to consider too. The conductive filler in one- or two-part materials can potentially separate out from the base resin and sediment onto the bottom of the container necessitating the need to mix/stir the material to evenly re-suspend the conductive particles before use. Storing the adhesive in a refrigerator at around 5°C will slow the process and help prolong its shelf-life.

Some conductive adhesives however, need to be shipped and stored in deep freeze. The catalyst curing mechanism is held in suspended animation until the material is thawed and ready to use. Of course, this type of material can have considerable and costly waste if the complete container is not used as it cannot be re-frozen.

With an ever increasing range of mobile communication devices and electrical goods generally, it is crucial to have good RFI shielding of components and/or products to prevent electromagnetic interferences. Eurobond has a range of electrically conductive adhesive coated foils and conductive transfer adhesive tapes suitable for bonding, masking, shielding, surface protection and electric vehicle battery cell electrolyte sealing tape.

Typically electrically conductive adhesive tape will have a shelf life of approximately two years and is not particularly affected by adverse temperatures during storage. Conductive tapes can be supplied in a roll format, of varying widths, lengths and thicknesses. Their conductive tape products have excellent properties for the high specification demands of the electronics industry in the 21st-century.

High grade acrylic, silicone and electrically conductive adhesives are used in conjunction with the best available films and metal foils to give outstanding results for high-performance consumer electronics, aerospace, automotive, industrial electronics and telecoms.

For more information talk to Eurobonds’ technical team on 01795 427888 or click here.

Bonham Drive

Eurolink Industrial Estate

ME10 3RY

UNITED KINGDOM

+44 (0)1795 427888