Posted to News on 31st Jan 2022, 08:57

Essentra Components cuts assembly time by 10%

Working alliance with metal parts and assemblies specialist Conceptole brings important gains

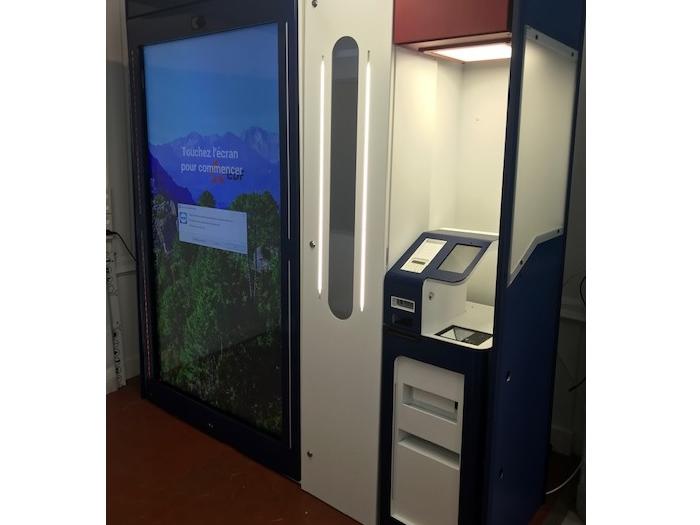

Conceptole is a French specialist in the design and manufacture of standardised and custom metal parts and assemblies. Its work encompasses telecom cabinets, street furniture, medical equipment, winegrowing equipment, signage, design, machine wrapping and terminals.

Its forward-thinking approach has enabled growth, and a reputation for quality and reliability. It needs those same qualities from suppliers, which is why it works with Essentra Components.

Conceptole’s cabinet designs called for a variety of components, ranging from access hardware to cable management. On-time delivery of these items was critical to ensuring their processes ran seamlessly. However, the companies from which it was sourcing components required long lead times, which threatened its own ability to meet deadlines. Its suppliers were also failing to provide technical support and answer questions. It was time for a change.

Reliable partner

Conceptole needed a reliable partner. It met with the Essentra Components team and visited the Roissy-en-France site. Experience convinced the company that Essentra Components was the partner who could provide the proactive support it required.

Working to short deadlines, Essentra Components delivered high volumes of stock. This included hinges, locks, gasketing, rails, swing handles, cams, spacers, feet and cable management solutions. To make the service even more hassle free, Essentra Components next delivered the components in kits.

These kits contained the components that each cabinet needed, which made for faster assembly during the manufacturing process. Essentra Components' support also included prototyping, free samples, and custom and modified products.

With Essentra Components’ timely support, Conceptole was able to manufacture its designs with peace of mind and without interruptions to their schedules or processes.

Operational savings

Instead of ordering components separately, Conceptole received kits that grouped together the components needed to produce each cabinet. This reduced assembly time during production by 10%. Conceptole also received operational savings through the partnership in purchasing, logistics and finance.

With large stocks available, Conceptole’s purchasing, logistics and finance departments had an easier time ordering the components they needed, the company says. This allowed it to concentrate on the daily running of the business. The kits also addressed another issue, in that components were delivered at the same time, specifically aligned to the needs of the production line, enabling the production team to be more productive.

Ongoing support

Essentra Components remains committed to Conceptole and continues to deliver high-quality components quickly against its required lead times. Essentra Components also provides support in other areas, such as working with Conceptole’s R&D department in the prototyping stage to find the best solutions and components for their applications.

Essentra Components consistently provides crucial technical support, where there was none previously. As its needs are consistently met, Conceptole has committed to consolidating their purchasing with Essentra Components.