Posted to News on 24th May 2023, 08:50

Essentra exceeds sustainability targets and launches new customer-led strategy

Essentra Components reports that it has exceeded its 2025 Scope 1 and 2 emissions targets and is reshaping its sustainability strategy to focus on helping customers achieve their sustainability goals.

According to the latest figures published in its 2022 Annual Report, Essentra’s components manufacturing operations have reduced direct emissions by 27% and emissions intensity by 35% since 2019. These results exceed the 2025 target of a 25% reduction in emissions intensity, three years ahead of schedule. These results support Essentra’s aims to reach Net Zero in its operations by 2040 and along its value chain by 2050.

The business is also ahead in other targets. In 2022, 12 component sites, double that of the previous year, achieved Zero Waste to Landfill, and overall waste intensity has reduced by 25% against the 2019 baseline, meeting its 2025 target ahead of schedule.

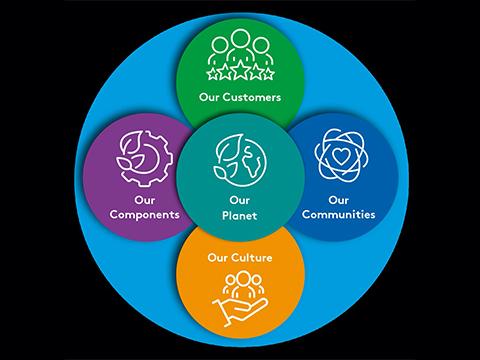

In publishing its results, Essentra has also revised and is expanding its sustainability strategy across five pillars: the planet; its components; its culture; its communities; and Essentra’s customers. For the first time, it is setting Scope 3 emissions targets which will be science-based and independently assessed and reviewed in line with the Science Based Targets initiative (SBTi). These new Scope 3 emissions targets will support both Essentra’s own ESG goals and those of its customers.

Essentra is also innovating with new sustainable materials. In 2022, it successfully completed 29 new product trials, and today, recycled polymer makes up 10.8% of total polymer materials used. The plan is to use 20% recycled materials by 2025. Most LPDE products manufactured at the Kidlington site in the UK use 50% recycled content, and many are 98%. These component products help Essentra’s customers to reduce their own product emissions and avoid Greenhouse Gas (GHG) emissions in their supply chain.

Essentra has also made progress in sustainable packaging materials; all plastic packaging at Kidlington comprises 30% recycled materials, against Essentra’s target of 50% by 2030. More innovative technologies such as recyclable and bio-based plastics, will be explored to reduce the company's and customers' environmental impact even further.

Jennifer Spence, head of sustainability strategy, says the business has made exceptional progress against its original sustainability targets: “Our new sustainability strategy is all about revising and upscaling our future commitments to reducing our emissions, achieving Net Zero and using more sustainable materials in our production processes.

“Our aim is to reduce not only our own environmental footprint but also support our customers in delivering their own sustainability targets. We’ll do this by continuing to innovate and advise on how our components can help develop a ‘win-win’ for us all.”