Posted to News on 31st Aug 2021, 08:57

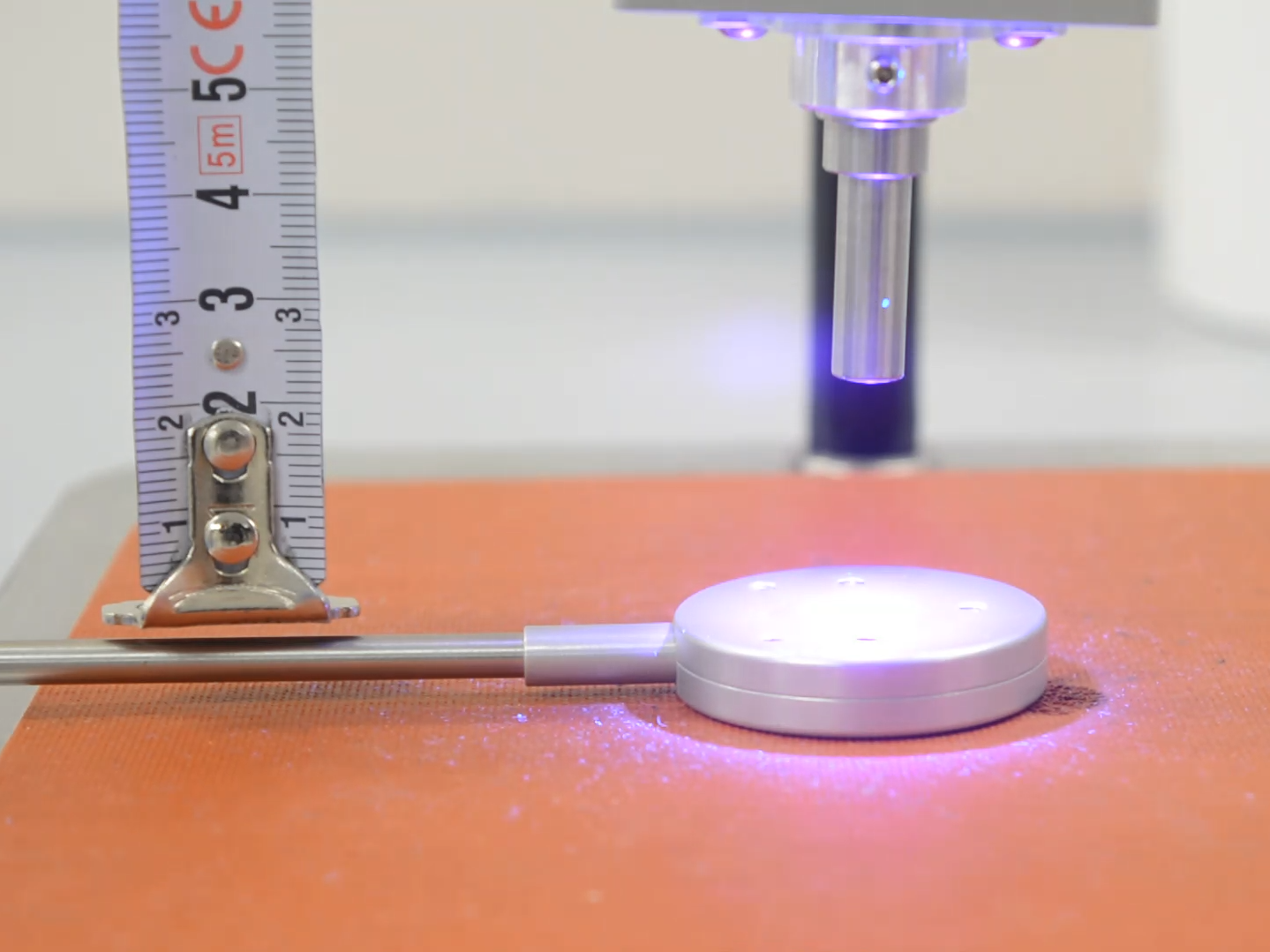

How to nail your UV adhesive curing process

New guide aims to boost manufacturers' knowledge and confidence

To help manufacturers gain confidence in their UV curing adhesive processes, adhesives specialist Intertronics has released a new whitepaper, ‘Nailing your UV adhesive curing process’. The whitepaper discusses the key UV curing adhesive process variables that need to be understood, and either eliminated or kept within acceptable tolerances, to achieve accuracy and repeatability.

"There are many benefits to using light curing adhesives and coatings, including process speed and simplicity, which lead to increases in productivity. To gain confidence in their process, manufacturers must qualify the process to achieve clarity and control over the variables at play," states Intertronics.

Onerous exercise

In certain regulated industries, such as medical device manufacturing, the process requires validation, a more onerous exercise that involves collecting and assessing data from process design right through to full production, to establish scientific evidence that the process can deliver quality product consistently. There also needs to be a clear plan for maintaining and verifying the process on a continued, long-term basis.

“The two principal focus points for process qualification are making sure the adhesive has undergone optimal cure and that the adhesive has been applied in the correct quantity and location,” explains Peter Swanson, managing director of Intertronics. “In both cases, the key is to identify process variables. These can then be monitored and documented to ensure the system is repeatability and consistently within the limits established in testing.

“The more variation a manufacturer can eliminate, the better,” adds Swanson. “But, if the variation can’t be eliminated, it can be understood and accommodated by the process. Every application is different, so it is important to qualify the process by using production parts, with the final specified substrates and manufacturing tolerances.”

Understand and managing the process

The whitepaper discusses the different parts of the process to understand and manage, both for curing and adhesive dispensing. It defines and explains how to measure 'full cure', gives guidance on determining the adhesive dose required for full cure, using empirical testing by varying intensity or exposure time, and discusses how to calculate a safety factor.

Since LED UV curing lamps and mercury arc curing lamps are fundamentally different technologies, the whitepaper explains the different variables to watch out for with each and explains how to assess them using a radiometer.

“Because there are so many nuances between applications, the best approach to process validation is to partner with an experienced adhesives supplier,” advises Intertronics. To read the guide on the Intertronics website, click here.