Posted to News on 14th Oct 2022, 09:12

Improving overmoulding adhesion with plasma treatment

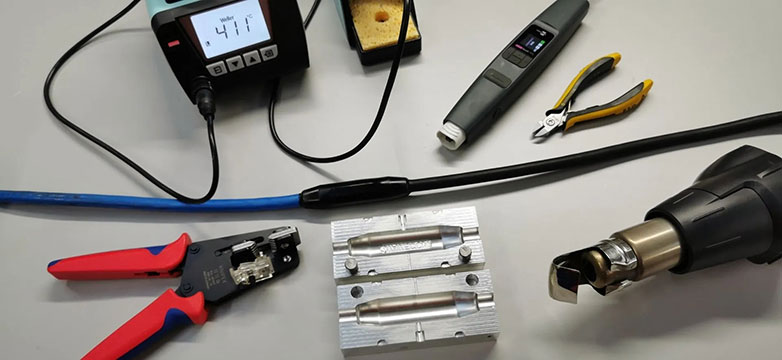

To help improve an overmoulding process, adhesives specialist Intertronics has supplied cable assembly manufacturer Wavecon with a piezobrush PZ3 handheld plasma surface treatment device.

Adopting the PZ3 means Wavecon can prepare surfaces for bonding in five seconds rather than 30 minutes and reduce chemical use to improve health and safety, achieving quick return on investment.

Founded in 2020, Wavecon specialises in cable solutions for subsea assemblies, offering a range of options from the supply of replacement cable harnesses and wired assemblies, through to fully designed and manufactured bespoke assemblies for specific applications. From the outset, the company decided to build an end-to-end manufacturing process, using high quality equipment, machinery and tooling, to retain 100% control over product quality.

Overmoulding is used to form a watertight and strong mechanical seal around cable assemblies used in harsh environments. Wavecon’s overmoulding process can apply to a wide range of materials depending on the application, including polyethylene, chlorinated polyethylene (CPE), polyurethane, rubbers, and neoprene. Because many of these materials have low surface energies, it causes poor wettability and bonding, creating an adhesion challenge. To improve adhesion, Wavecon had tried abrading the surfaces, and painting them with liquid primers. Because the use of primers introduced some delay to the process, and led to variable results in some applications, the team turned to Intertronics for help.

“After detailed discussions with the Wavecon’s team, we recommended using the piezobrush PZ3 to treat the outside of the cable before inserting into the mould for overmoulding,” explained Paul Whitehead, strategic accounts manager at Intertronics. “Plasma treatment can raise the surface energy of the substrate, alter the chemical groups on the surface to improve wettability, and creating bonding anchors on the surface.”

The PZ3 uses cold atmospheric plasma technology and therefore does not involve significant heat. The PZ3 is unique in that it is a handheld cold plasma device, enabling uncomplicated and manual optimisation of surfaces for a relatively low cost. The PZ3 requires no specialist knowledge to operate and is equipped with several in-built process control features that can be adjusted using a simple user interface.

“With the PZ3, we could remove the use of primers in several applications,” explained David Stout, director at Wavecon. “This means our team is using fewer chemicals, which is better for operators, reduces the health and safety requirements, decreases risk, and is better for the environment.

“In addition, the PZ3 has helped us decrease production time by removing the wait time for primers to set, as well as the need for repriming – the PZ3 can do in five seconds what would previously have taken up to half an hour,” added Stout. “We pride ourselves on quality, and the PZ3 has helped us to develop a reliable process that delivers quality every time.”

The Wavecon team has since done extensive testing in a pressure chamber at 466 bar, the equivalent of 3000 metres deep, demonstrating high quality and excellent durability. Wavecon delivered its first product in January 2021 and is now growing rapidly. In the next few years, the company is looking to hire new staff and develop new product ranges to continue its growth.