Posted to News on 18th Nov 2021, 08:57

Inside view on enclosure sealing

Hints and tips for specialist enclosure manufacturers and vehicle builders

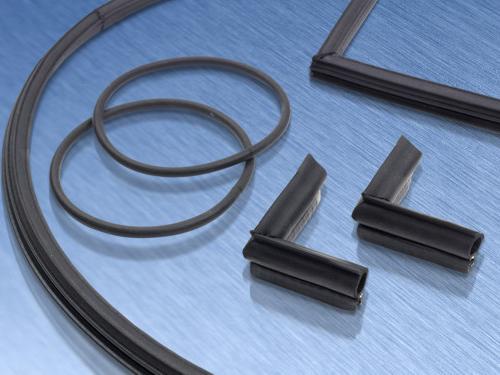

Extruded rubber profiles are used for sealing doors and panels in a variety of industries, including the aerospace, automotive, lighting, appliance, electronic, construction, marine, medical and general industrial applications.

This section can be quite simple – ie, circular, annular, rectangular profiles – or very complex (window profile, rubber car seal). Some common materials used in rubber extrusion include EPDM, SBR, (CR – neoprene), silicone, (NBR – nitrile) and (NR- natural rubber).

In this article, Andy Billingham, managing director EMKA (UK), assesses their particular value in connection with applications such as:

- Edge protection profiles, sealing profiles with and without metal carrier

- Sponge rubber profiles with and without bonding (Self-adhesive foam)Rubber glazing and filler profiles

- Dual hardness rubber profiles

- Door sealing profiles

- Custom-made products, frames, rings, lengths, butyl, mastic, flock coating, notching, gluing, slip coating etc.

For optimum effectiveness, the compression of a typical sealing edge protection profile should be a maximum of 50%, as otherwise the compression and recovery can be adversely affected. It is recommended the profile should be compressed 30-40%.

An excellent solution to the common problem of sealing corner joins is the use of spliced joints. This process effects a joint that is particularly effective where there is a requirement for a continuous ring or frame, such as windows or automotive applications. Spliced joints ensure that the resilience and dynamic properties of the profile are maintained throughout the joint. Frames and rings can save greatly on assembly time, while significantly enhancing sealing performance.

Wide range of gasket offerings

Specialist gasket sections are offered by many manufacturers in flame-retardant, low-smoke, low-tox materials compliant to relevant standards, while extruded gaskets for enclosures and other purposes are available in self-adhesive, self-grip (clip-on), channel fixing and window type (with expansion insert). The range includes EPDM, NBR, CR, PVC and silicone, as well as fire protection specifications and many with EMC-compatible coating.

Specialist installations, such as coaches, motor homes and caravans, also require moulded sections to suit doors, windows and ventilation panels, as well as external storage compartments, and often require specialist materials or finishes:

- Flock coating – a scratch-free coating to provide a smooth sliding action popular for windows

- EMC (coating) – for electromagnetic compatibility to maintain or increase the protection of sensitive equipment from external EM radiation

- Vulcanising – a tough resilient way to form joints, frames and continuous sections

- Slipcoat – a simple coating process to redress the effect of friction

- Silicon – high temperature, fire resistant for rail, tunnels etc., also food industry.

In selecting the right mounting type for every installation situation, we find that this is a decisive factor in a successful installation:

- Self-clamping profiles have an internal steel or wire clamping band and thus ensure that the seal is held securely on the sheet edge.

- Stamped or wire spiral carriers use steel or wire clamping strips, this enables edge protection profiles to retain well even without adhesive bonding. Steel strapping generally shows a higher clamping effect than wire strapping.

- Plugged or insert profiles do not have a metal insert and are not glued, being self-retained. They are plugged into a gap or channel between two edges and safely seal the cavity in this way.

- Clamping profiles are ideal for screwless insertion of windows. The use of a rubber clamping profile guarantees a firm, durable and rattle-free connection in many types of special panel, vehicles, mobile cabins and large machines.

- Self-adhesive technology is particularly suitable for economical and quick fastening seals where the profile is glued onto a flat section with an adhesive strip which contains integrated cotton threads for a stretch-free installation.

With sealing profiles and clamping profiles made of 100% EPDM, EMKA have successfully enhanced gasket quality with high resistance to weathering, also UV radiation and acids, which makes them particularly durable – at no extra cost.