Posted to News on 22nd Aug 2023, 15:06

Investment keeps automotive supply chain agile and just-in-time

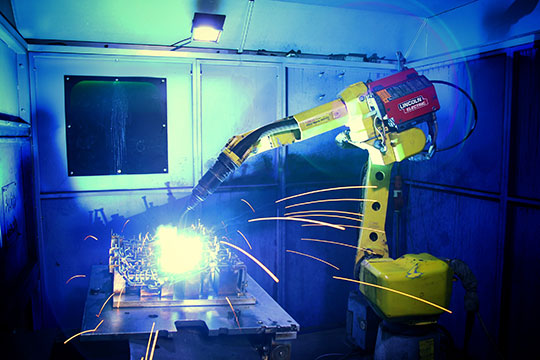

William Hughes has adapted quickly to a serious increase in demand from a tier-one automotive seating customer, thanks to a major new investment in robotic welding cells and associated tooling and fixtures.

The investment at its plant in Bulgaria is in reaction to the ramp up in popularity for a recently released sports utility vehicle (SUV). Currently selling beyond production capacity, the vehicle is available with multiple seating configurations, so the demand for seating frames and hardware has seen commensurate growth.

William Hughes' manager for Bulgaria, says: “The output for the various seating modules and formats is now about 30% higher than the original anticipated peak production plan. And with the automotive industry relying on just-in-time delivery for primary modules, such as seating, we knew that we had to pull out all the stops to ensure our tier-one customer would not disrupt production.

“The seat frame for this model is unusually heavy duty – being a welded-wire assembly designed to complement the vehicle’s impressive off-road reputation,” he continues. “The new welding cells, Fanuc robots and additional tooling have enabled us to meet our delivery quotas for this model and, indeed, other projects in the future, which will also benefit from the added efficiencies we can bring through automation and fabrication at scale.”

Demand for the new SUV is showing no signs of slowing so there is the potential for additional investment in the future. “The Bulgarian factory is ideally placed to satisfy the demands of the Eastern European OEMs,” he concludes. “With hand-to-mouth delivery, being on their doorstep – or at least in the same neighbourhood – removes many of the logistical hurdles. And from a technological standpoint, investment like this, and in wider capabilities such as spot-welding for back frames, puts us in a perfect position to satisfy a huge array of OEM demands.”

The investment in its Bulgarian facility cements the company’s commitment to its customers and Eastern European operations. Indeed, the plant is already being asked to investigate newer seating variants, with its customers being confident that William Hughes can quickly ramp up and scale production to cater for any demand level – now and in the future.