Posted to News on 11th Jul 2022, 09:44

Is your DIN rail technology future proof?

CamdenBoss has breathed new life into an old-time customer favourite – the CMEB extendable DIN rail terminal enclosure. Designed and improved with the engineer in mind, new features have been built into the enclosure.

DIN rail enclosures often house crucial equipment in electrical and electronic assemblies, frequently consisting of circuit breakers, switches and power management devices. The DIN rail itself is of basic design and are made to fit industry standard rails such as 35mm top hat and 15mm top hat, with the former being the most common type used. Other types can be G rail and C rails.

Many different enclosure designs saturate the market and with this in mind, it is important for manufacturers to offer their customers products that not only provide adequate housings that meet industry standards, but also features that can aid in the assembly and maintenance of such devices.

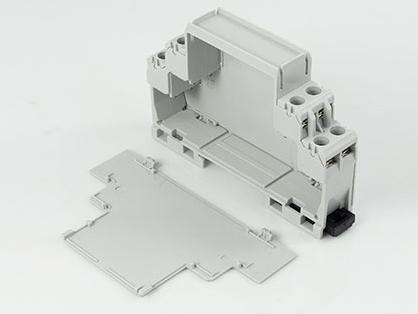

The CMEB enclosure is built up of the main housing body, eight pre-fitted saddle washer connectors with adjoining solder tags, a lid and two removable side panels. Customers are able to select from a variety of kits such as open top, with either a solid grey or clear lid, or solid top that provides a slight recess for the addition of keypad membranes or displays.

One of the main issues that the CMEB challenges is the separation of the internal space, allowing the enclosure to deal with different levels of supply voltage in application. Various PCB positions become available to an extended enclosure providing a way of achieving this separation. Alternatively, input wires can be connected at the terminals from the top of the mounted enclosure with output wires being fed out of the bottom.

A single housing makes use of a planer PCB, following the side profile of the internal face. An extended housing gains the use of horizontal PCBs due to the PCB slots found on the purpose-built extension arms.

Historically, the CMEB operated using only one attachable side panel. The downside to that was the challenge presented when soldering up the internal components or PCB. This was improved by simply providing two detachable side panels, opening the enclosure fully, allowing for access to the internal space. What’s more is that these end panels are attached using a simple snap fit method, requiring no screws. This significantly speeds up the assembly time, in addition to providing easier maintenance later down the line, should it be required.

DIN rail enclosures are often required in panel-built applications where lots of connecting wires and cables are used. Due to the applications, they are built for. DIN rail electronics can be found in our homes, offices or factories operating as power supply equipment, switches, safety devices such as RCDs, relays and much more. This makes them an integral part of the industrial and commercial world. With this in mind, CamdenBoss looked to improve upon the wiring capability of the CMEB, upsizing the compatible wire size to a M3 screw with 7mm saddle washer. This improvement to the pre-fit connectors provides an electrical rating of 8A/250V.

The CMEB joins the list of CamdenBoss UK-made products, tackling the current global supply chain issues that a lot of us are facing within the electronics industry. This allows the company to offer competitive pricing and lead times to its trusted distributors, or for bulk orders, direct from its warehouse to customers.