Posted to News on 10th Dec 2020, 12:28

Light curable adhesive for bonding laminates

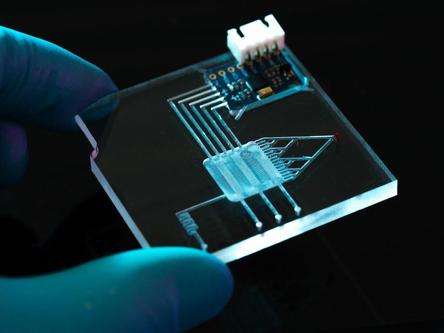

Intertronics highlights an LED UV and broad-spectrum light-curable adhesive for bonding COC/COP film laminates. It is also said to be suitable for other difficult-to-bond-to plastics such as those used in the assembly of in-vitro diagnostics (IVD), Lab-on-a-chip (LOC), and other point-of-care medical devices

Dymax MD® 1172-M-UR is an LED UV and broad-spectrum light-curable adhesive for bonding COC/COP film laminates and other difficult-to-bond-to plastics used in the assembly of in-vitro diagnostics (IVD), Lab-on-a-chip (LOC), and other point-of-care medical devices. Intertronics says that the adhesive may also be of interest to manufacturers involved with the design of COVID-19 rapid diagnostic applications.

The adhesive is moisture resistant, soft and flexible with a shore hardness of A70, and has a viscosity of 1,100 cP for improved wetting. Dymax 1172-M-UR is formulated with Dymax Ultra-Red® fluorescing technology for simple visual post-cure quality inspection of the bond line area. After cure, when exposed to low-intensity black light (365 nm), the material fluoresces bright red, making it easy to see on plastics that naturally fluoresce blue in color, like PVC. This ISO 10993-5 Cytotoxicity approved product is ideally suited for rapid diagnostic applications, microfluidics, reservoir and transducer assembly, and medical potting applications.

Intertronics confirms that the product is LED optimised to cure in seconds on exposure to LED UV (365 nm) or broad-spectrum light energy. By using this product in conjunction with a Dymax LED light-curing system, optimal cure time can be achieved, providing users with significant advantages over conventional lamp-curing systems including cooler curing temperatures, more consistent cure results, and lower intensity degradation over time.