Posted to News on 17th Aug 2023, 11:00

Machine heat recovery system for heating factories efficiently

Engineers from igus are now using a simple, in-house technology for heat recovery. It uses the waste heat from machinery to heat factories and industrial units, saving energy costs and CO2 emissions. Now igus has made the details of the technology available online to industrial companies, for free.

If all injection moulders worldwide were to use this technology, igus calculates that over one million tons of CO2 and over 548 million m3 of gas could be saved.

Energy prices are rising – even with any recent price falls, the longer trend is rising. Climate change is accelerating. En route to the goal of climate-neutral manufacturing production by 2025, three igus engineers have set out to eliminate the use of fossil fuels during production.

They initially experimented with car heat exchangers from and computer fans. The experiments grew and with time, a bigger and bigger area could be heated. After six months, the new concept called ‘Machine Heat Recovery System’ (MHRS) succeeded in heating one of the large production halls of igus’s factory in Germany using waste heat from the injection moulding machines.

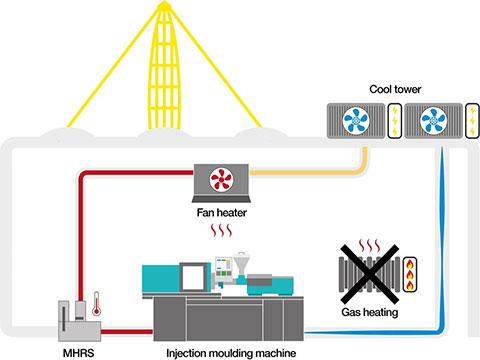

Depending on the heating requirements, MHRS directs the hot water flows from the cooling circuit directly to the fan heaters, while simultaneously ensuring that the machines don’t overheat. Since heat is extracted from the hot water as it passes through the fan heater, the demand on the factory’s cooling tower is reduced, meaning that the mains gas heating system is not required or reduced, and less electrical energy is used for cooling. Fluctuating cooling circuit temperatures can be variably adjusted by the system.

The MHRS does not use the familiar but expensive heat pump to exchange heat and does not take a detour via a heat exchanger, which would lead to temperature losses. There is also no need to feed in the waste heat from air compressors. igus is already gradually reducing compressed air energy to reduce energy costs.

“With this in-house heating system, we will be able to reduce gas consumption to almost zero in the future. In addition, we will need less electrical energy for cooling,” says igus CEO Frank Blase. “This saves us costs and reduces CO2 emissions and thus relieves the burden on the environment.”

How the new gas-saving heater works

Hydraulic motors of the injection moulding machines heat up during their operation. Just like in cars, they need cooling to protect against overheating. Cooling towers are used in factories, supplying cold water and to the moulding machines via pipes, the hot water then returns to the cooling tower. When re-cooled, the heat escapes into the atmosphere and energy is lost.

With the MHRS, some of the heat from the cooling circuit is tapped via a flow control system and directed into the heaters, which are located next to the old gas heating fans. To stop these heaters from clogging immediately, the solids suspended in the water are filtered out. The warm water enters the new fan heater and deactivates the old device.

A fan located on the heater finally distributes the heated air in the hall. Only then does the water flow back to the cooling tower and the cycle begins again. Since heat exchangers are not used, the system can also be operated in the low-temperature range.

A concept for the industry

“We are convinced by our concept and plan to rely entirely on machine heat as heating in production and offices in the future,” says Dennis Berninger, factory manager at igus in Cologne, who is leading this project. “The next plan is to equip the large logistics centre with nine fan heaters. Here alone, around 31.5 tonnes of CO2 can be saved annually. This is an important step for igus to get closer to the goal of being carbon-neutral with its buildings and production by 2025.”

Spurred on by the success, igus is making the technology available to other industrial companies as well. A calculation devised by igus states that over one million tonnes of CO2 and over 548 million cubic metres of gas could be saved if all injection moulders worldwide were to use the technology. This corresponds to the annual gas consumption of 238,434 German four-person households (see calculation below).

“We see great potential for the MHRS in the industry, which is why we want to make the concept available to other companies free of charge,” says Blase. “During our research, we did not find any published, precise instructions on how to use heat recovery systems in factories. We are already providing information on how MHRS and the developed control device works on our website. More and more details are being added."