Posted to News on 16th Jun 2025, 10:40

Multi-stage cold forming for individual multifunctional parts

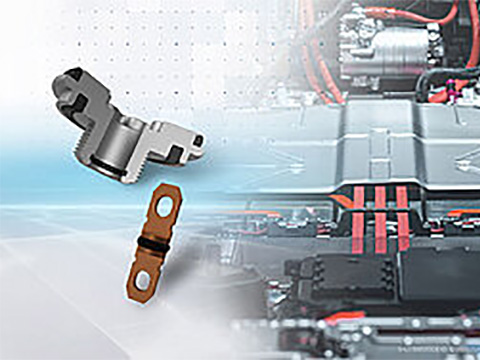

Conform components are customer or requirement-compliant components that are manufactured in a multi-stage cold forming process. With Conform Next, ARNOLD UMFORMTECHNIK is now going one step further.

In addition to tool developments, existing systems are further developed, optimised and adapted with a view to component specifics. This allows the fastener manufacturer significantly more flexibility and efficiency, particularly in the production of highly individual component geometries.

The forming process of the individual Conform Next components entails a longer cycle time. This makes it possible to link the processes economically. In addition, these are usually expensive and high-quality components that are also sensitive to vibration and must be brought into the correct position for machining. Thanks to the slower forming process, testing and assembly steps can now also be integrated directly into the process. This means that the formed components do not have to be moved to another machine or even to another plant. This saves logistics costs.

In addition to process integration, it is also possible to react much faster if errors are detected, as the Conform Next process already starts at the development stage.

In principle, the Conform Next process is suitable for any components that need to be complex or individually designed. Accordingly, it can be used in many areas and industries as a substitute for more expensive turning or milling.

Alternative to expensive turned or milled parts

The applications and design of Conform Next products are extensive. ARNOLD's production options cover the manufacture of complicated external contours as well as blind and through holes or short, difficult to transport parts and products that require internal hole machining. No matter which of the many Conform Next components is involved is certain: The non-cutting process can sometimes result in significant material savings.

According to ARNOLD UMFORMTECHNIK, designers and developers benefit from the fastener manufacturer's expertise right from the development phase and prototype construction. ARNOLD's engineering tools can be integrated into the development process and provide the necessary parameters for an early large-scale production check, both for cost-efficient and optimized development and production steps as well as for functional prototypes in large-scale and near-series quality. Right from the start, the focus is on readiness for large-scale production. Necessary adjustments can be incorporated into the product development process at an early stage. This ensures shorter process and lead times for customers, a high degree of flexibility and saves time and development costs.

At ARNOLD UMFORMTECHNIK, the initial focus is on customers from the automotive industry, with an emphasis on electromobility and lightweight construction. However, according to the company, other areas of application are conceivable. With the expansion of production capacity for the Conform Next division at the Rauhbusch site, ARNOLD UMFORMTECHNIK is responding to the changes in the mobility industry and increasing customer interest in Conform Next components.