Posted to News on 1st Dec 2020, 09:57

Q&A - ONSERT opens up design opportunities

A unique partnership between mechanical fastening experts Boellhoff and adhesives manufacturer DELO has been bringing a wide range of benefits to design engineering teams

A unique partnership between mechanical fastening experts Boellhoff and adhesives manufacturer DELO has been bringing benefits to design engineering teams.

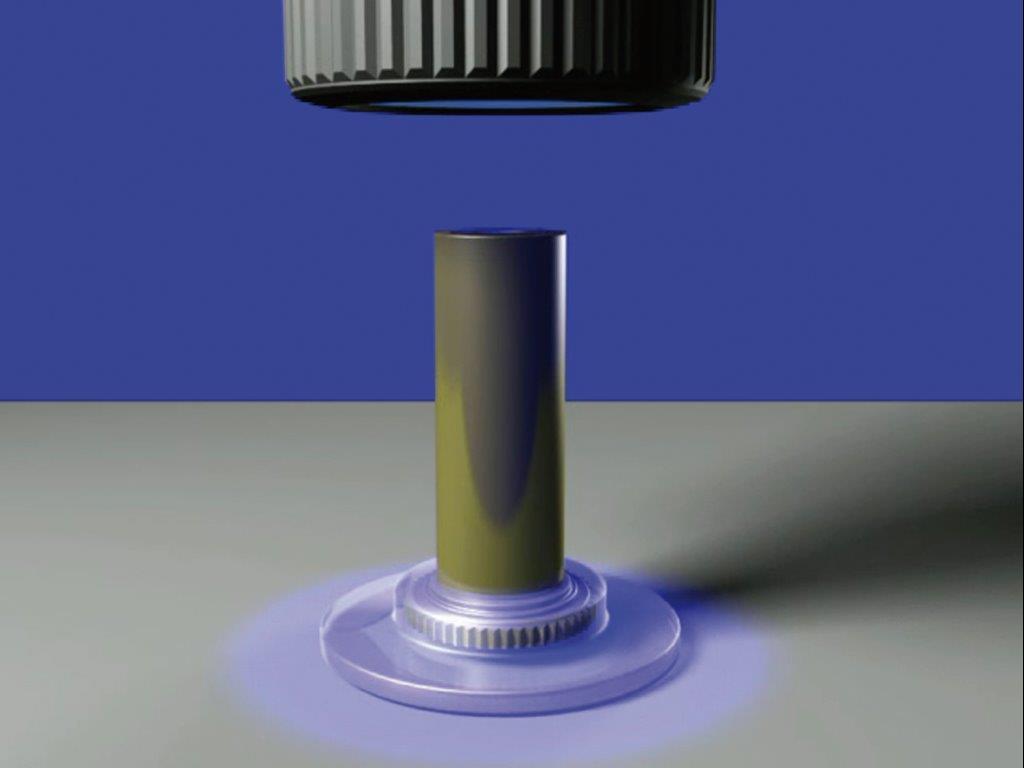

The two suppliers have teamed up to provide an innovative new fastening process that combines the advantages of mechanical fastening with those of bonding. Designed for use where a strong, secure mechanical threaded fastening is required in lightweight applications, the innovation has been named ONSERT.

In this Q&A, we find out from Boellhoff about the strengths and versatility of the solution

F&B: First, tell us what exactly ONSERT is?

Boellhoff: The ONSERT from Boellhoff allows the permanent adhesive bonding of various fasteners to a wide range of materials with either an internal or external threaded stud when welding is not an option.

F&B: How long have Boellhoff manufactured ONSERT?

Boellhoff: ONSERT is a relative newcomer to the Boellhoff portfolio. As a specialist in mechanical joining systems, we have developed, through a partnership with German adhesives company DELO, the experts in intelligent adhesive technology, a versatile fastener that can be mounted to non-weldable lightweight structures, opening up a raft of new design possibilities.

F&B: What are the benefits of ONSERT?

Boellhoff: The adhesive used is cured with seconds (<4 seconds) giving full mechanical load capacity immediately the adjusted lamp geometry on the Boellhoff tool means optimal curing is guaranteed directly after light curing. Another key area of benefit is in applications where the need for lightweight materials is combined with a requirement for a threaded fastener.

Typically, the ONSERT will be used to attach additional items to carbon, composite or plastic panels, or to provide a means of securing the panels themselves to an existing structure. However, the use of ONSERTs is not restricted simply to panels or plastics and composites: because they can also be used with metals, aluminium alloys.

They have also proved useful for applications where items are required to be mounted onto glass panels too. Whether steel, aluminium sheet, plastics or glass. Several materials, one procedure. The simple fixing method for all types of components.

F&B: What type of fasteners are available?

Boellhoff: ONSERT Basic fasteners, such as screws, threaded bushes or snap connectors are provided with a transparent plastic sheath. The geometry will be chosen deliberately, so that a sufficient bonding surface is available.

Generally, all geometries which can be produced by injection moulding are possible. Screwed connections on plastic mouldings, cable ties, detachable and non-detachable snap connections, adhesive SNAPLOC fasteners etc can be applied to materials, such as CFRP, FRP, glass, lacquer, cathodic dip coating, plastic, such as PCABS, PA and blends.