Posted to News on 11th Dec 2020, 08:58

Retaining ring has a bearing on robotics success

When a manufacturer of miniature robotic systems was faced with a problem trying to introduce pre-loading of some miniature bearings in an exoskeleton application, TFC had the answer

Because the assembly relied on ultra-thin wall bearings, the supporting bearing faces were little more than 1mm wide and the axial space for the pre-load assembly was restricted. With the axial and radial space at such a premium, the use of a conventional wavy washer and circlip combination was deemed impractical given its combined thickness - and the effective diameter of a conventional circlip was also unacceptable in the space available.

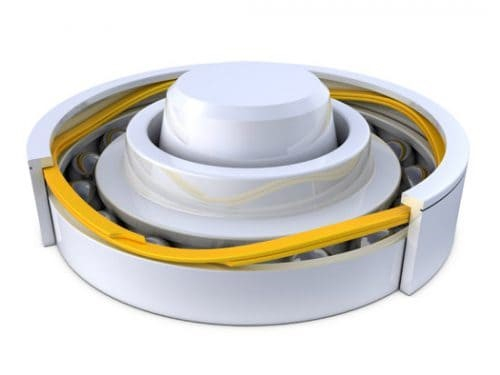

As a result, the TFC technical team suggested using a single component to provide a compact lightweight solution. The Smalley Wavering® is a spiral formed retaining ring (or circlip) but with the additional feature of compressibility. Designed to fit in a groove, it applies pressure in two directions against the groove wall and also against the assembled components. In this application, the Wavering® was able to provide take-up for tolerance build-up and also eliminate the possibility of looseness developing as a consequence of vibration during operation. Further, despite the design being bespoke to the application, the no-tooling method of manufacture meant there were no additional tooling costs or long lead times involved for the customer.

TFC says that the use of its Smalley Wavering® meant the customer was able to improve the reliability of its product without incurring the considerable costs of modififying the assembled components. The constancy of the force with the TFC product at operating height, when compared to a conventional die-stamped wavy washer is stated to have further improved the reliability of the customers™ product. In addition, the application of a single component also reduced assembly time and removed the risk of error during assembly.